Adjusting Drapery Yardage Requirements for Pattern Repeat

In a previous blog from last May I described in detail the

“how to” of calculating yardage for draperies and in that blog I promised to

explain how one adjusts for a fabric pattern repeat that will require matching.

The basic formula is simple, and I will talk about that first for persons who

want to get to the point of it and move on.

|

| A Matched Pattern Allows the Treatment to Look Uniform all the way Across |

To adjust drapery yardage calculations for matching the

pattern horizontally across a drapery panel or treatment: (Going back to the previous blog, this would be step 2B) After

performing the necessary “ADD TO LENGTH” calculation for your particular

treatment, the adjustment for pattern repeat is made.

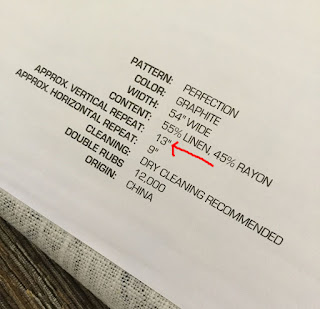

FIRST, find the VERTICAL repeat of the pattern. This is

a curious but critical phenomenon to remember, but when calculating a Horizontal pattern match, the Vertical repeat of the pattern is the

dimension that is required. The vertical repeat of the pattern (if you don’t

have yardage in hand) can be found listed on the supplier’s or manufacturer’s

label which is usually attached to the back of the fabric sample.

|

| Example of a Manufacturer's Tag |

Notice the vertical repeat is stated as “approximate”, this

is because the repeat of the pattern may not always be exactly the same from

manufacturer run to run, so keep this in mind when placing the final order for

fabric as a little extra may be required for a perfect pattern match.

SECOND, once the

vertical repeat of the fabric pattern is determined, take the adjusted “add to

length” dimension and divide it by the vertical repeat. In the example in the

previous blog this was 118 inches, and since in my example above the

approximate vertical repeat is 13 inches, we will use that for this example.

So, 118 divided by 13 = 9.076923.

THIRD, round UP

to the next whole number, 9.076923 rounded up, is 10. This means you will need

10 vertical repeats of the pattern in order to match it across the widths when

they are sewn together.

FOURTH, multiply

the result times the vertical repeat. 10 X 13 = 130 inches. So, instead of 118 inch

cuts or lengths of fabric, we will need 130 inch cuts. A difference of 12

inches per cut!

LASTLY, to

complete the total yardage calculation, return to the previous blog step 5

where the total yardage is calculated, and substitute the repeat adjusted cut length number. In the example 4 cuts X 130 =

520 divided by 36, equals 14.44 yards. This is the new yardage requirement for

the drape in the example using a fabric with a 13” repeat.

The difference in yardage to match the pattern across the

width of the drape in the example is 1.19 additional yards, and because the

vertical repeat as stated by the manufacturer was “approximate” it is advisable

to also round UP the total yardage before ordering to the next whole yard. In

the example, I would order 15 yards to be safe.